Installing Laminate Flooring for Beginners

Wiki Article

The 9-Second Trick For Flooring

Table of ContentsThe Definitive Guide for Hardwood Flooring8 Simple Techniques For Wood FlooringThe Best Strategy To Use For Flooring StoresThe smart Trick of Hardwood Flooring That Nobody is Talking AboutThe smart Trick of Wood Flooring That Nobody is Discussing

These two components are blended prior to application. When the resin as well as the hardener are combined, they participate in a chemical reaction that creates cross-linking of the aspects as it treatments. The result of the chemical response is a hardened, rigid plastic finishing material that bonds well to most base layers.One of the various other considerable advantages of polyurethane flooring finishings is their curing time. In comparison, epoxy finishes need at the very least seven days to cure prior to they can be prepared for use.

Luka and his team were prompt, tidy and also very specialist. It was most definitely among my greater bids yet I feel like it was greater than worth the additional money.

Facts About Hardwood Flooring Uncovered

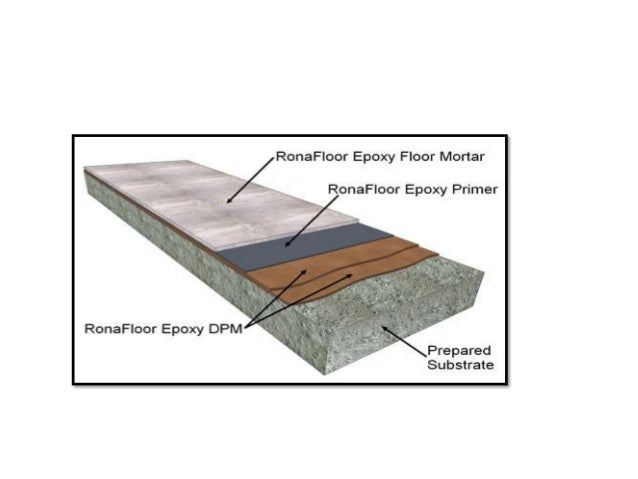

Epoxy is a high-performance concrete finishing that is made up of 2 major components: materials as well as hardeners. The resin as well as hardener are mixed with each other where a chain reaction takes place to create a stiff product. This material is solid, resistant to degradation, bonds extremely well to substratums, and is cosmetically pleasing.It's crucial to recognize the difference in between a high-performance industrial-strength epoxy finishing item and also an economical epoxy paint (what you can purchase from the local equipment store). As you proceed checking out, when we describe our systems that use epoxy we are referring just to the most effective high quality industrial-strength epoxy products offered.

To aid put this into viewpoint, think about an additional type of flooring - wood flooring. Naturally, no person needs to attempt installing plywood in their kitchen area instead of the 'pricey' wood boards that the pro's would install. That is because the outcome will certainly not work, it will not withstand, and will probably be harmful and untidy.

The smart Trick of Vinyl Flooring That Nobody is Discussing

So exactly what are epoxy flooring finishings? Epoxy floor coverings are generally two part solids based, solvent based or water based. Epoxy flooring contains a Resin part as well as a Hardener component, similar to epoxy glue. Regular garage flooring paints are one part oil based or water based. Top quality epoxy flooring wood flooring paints are neither one part, oil based nor water based as well as all epoxies are not the very same.

Positioning epoxy flooring in the same classification as traditional garage floor paints is like saying a Volkswagen Beetle is the same as a Ferrari due to the fact that they are both cars and trucks. Not understanding the distinctions between paints and the various kinds of epoxies will certainly result in you finishing up with a flooring that does not look right as quickly as you're done or a flooring that puts on and fails in short order.

Unworthy minority bucks you may have saved or invested even more on with another brand that was substandard. An epoxy flooring covering will certainly stick to your garage floor or any kind of concrete floor for that issue way better than any standard oil based, water or enamel paint, believe epoxy glue type attachment vs air duct tape adhesion.

Flooring Can Be Fun For Anyone

A good epoxy floor finishing when cured is just around tarnish proof as well as cleaning it is similar to cleansing your Teflon pan. Our epoxy finishings are offered in various shades with custom colors available for larger size floorings. We likewise have ornamental color flakes that can be added right into the epoxy for a granite type look.We have actually done every kind of floor there is with every kind of item ever before invented so we know specifically what works and also what doesn't work and also it's a factor why we are the largest online epoxy floor covering vendors. It means that with 100% solids you are getting 100% paint so that whatever you place down is what you obtain.

The component that evaporates is either solvents in the case of solids paints or water in the instance of water based epoxy paints. For instance, if an epoxy is 50% solids it suggests that 50% of the finishing you apply will vaporize away as official statement it dries. The reduced the percent of solids the reduced the quality is a good general rule, with water based paints being the most affordable high quality.

We identify these as pietistic concrete sealers. One Component Epoxy Coatings & Coatings That Don't Need Floor Prep One thing we understand for certain is that all the one component epoxies we've attempted don't work. They have a tendency to be thin, difficult to function with and also not a great idea when making use of shade flakes.

6 Easy Facts About Flooring Installation Explained

In much heavier flake applications the flake can really sink down onto the concrete definition you have little to no epoxy on the concrete. This is why we do not make use of shade flakes with our industrial finish. The skim coat is made to be a little thinner to saturate into the concrete and it works excellent of what it's created for.Annually there seems to be some new magic formula that hits the marketplace with outlandish assurances. Lately it has actually been "High Solids Epoxy" suffice. We say NO they are not, the majority of company's epoxies do not also equivalent our primers as well as definitely their high solids epoxies are even less certified.

A guide constantly makes for a much better job due to the fact that it includes one more layer of epoxy and also seals the floor at the same time. Some floor covering epoxies will assert to be a primer, an epoxy and also a topcoat all in one.

For instance our Shield Chip Garage Epoxy kit covers 575 sf. Let's claim your floor is 625sf. You either need to buy an Include On Half Set or you can Prime. Priming is the better method to enter this case, you obtain an additional layer of finishing and also helpful hints prolonged coverage of the epoxy.

Report this wiki page